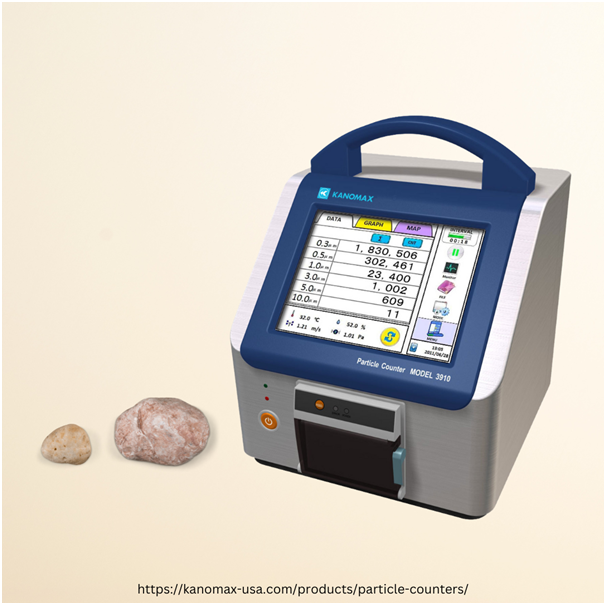

Particle counters are essential instruments for industrial applications that require accurate measurements of airborne particles. They are used in a wide range of industries, including pharmaceuticals, electronics, aerospace, and healthcare. Let us explore the features of a particle counter.

Size Range

Particle counters can detect and count particles in a specific size range. The size range is determined by the type of sensor used in the device. There are two types of sensors commonly used in particle counters: light scattering sensors and condensation particle counters.

Light scattering sensors detect particles in the range of 0.1 to 10 micrometres. These sensors use a laser beam to detect and count particles as they pass through the beam. The laser light scatters off the particles, and the scattered light is detected by a photodetector. The size of the particles is determined by the amount of light.

Condensation particle counter models detect particles in the range of 2.5 to 10 nanometers. These sensors use supersaturated vapour to condense particles onto a surface. The particles are then counted using a photodetector.

Data Storage and Analysis

Particle counters generate a vast amount of data, and it is essential to store and analyse this data effectively. Many particle counters come with software that allows users to download data to a computer for analysis. The software can generate graphs and charts that show the size distribution of particles, the number of particles per cubic metre of air, and the total number of particles detected.

Some particle counters and a water quality analyzer have built-in memory that allows users to store data directly on the device. This feature is for applications where a computer is not readily available.

Sampling Options

Particle counters can sample the air in various ways, depending on the application. The most common sampling methods are continuous sampling, intermittent sampling, and spot-checking.

Continuous sampling involves sampling the air continuously over some time. This method is present in applications where a constant flow of air is required, such as in cleanrooms.

Intermittent sampling involves using the viable particle counter at specific intervals. This method is evident in applications where periodic monitoring is required, such as in HVAC systems.

Spot checking involves taking a single sample of air at a specific location. This method is known in applications where quick measurements are required, such as in hospitals.

Portability

Particle counter devices come in sizes and shapes, ranging from handheld devices to large, stationary units. The portability of a particle counter is an essential consideration, depending on the application. Handheld particle counters are ideal for applications where mobility is required, such as in field testing. Stationary units are good for applications where constant monitoring is needed, such as in cleanrooms.

Ease of Use

Particle counters can be complicated devices, and choose a model that is easy to use. The user interface should be intuitive and straightforward, with clear instructions and a user-friendly design. The device should also be easy to maintain and calibrate, with minimal training required.

Accuracy and Precision

Particle counters must be accurate and precise to provide reliable data. The accuracy of a particle counter is determined by the calibration process, which involves comparing the device’s readings to a reference standard. The precision of a particle counter is determined by the variability in the device’s readings. The variability should be as small as possible to ensure the accuracy and consistency of the data.

Are you looking for a water quality analyzer to examine some things? Or are you searching for a viable particle counter for your industrial needs? Whatever that may be, you are always free to visit the website of Ansac Technology to learn more.

Comments